Plastic Grinding Milling Granulator adopts update design principles, employs the principles of grinding rapidly, agitating continuously, milling and fractioning to be heated with multi-knives and cooling and contracting. It produces granules from waste materials and angle materials such as the plastic films, filament, ribbons, pieces, soft plastic pipes, foaming materials, and degrading materials, and puts then into reproduction .It is the latest ideal granulating equipment to recycle plastics and reproduce.

Main Functions:

Main Features:

A: Milling, mixture and staining can be processed all in one

B: The machine takes up little area of land

C: It is characterized by simple structure and ease of operation

D: The interstitial of the blade can be adjusted with convenience of replacing.

E: It is characterized by high efficient in production and low consumption(1 ton of daily production ,and 200 degrees of electricity consumption ).

F: Granulate at lower temperature, do not damage molecular structure of materials basically, and do not damage physical performance.

Main Technical Variables:

| 1 | Capacity of Barrel | 150L | 100L |

|

|

| 2 | Output Capacity | 60-80kg/h | 30-60kg/h | ||

| 3 | Main Motor Power | 18kw | 15kw | ||

| 4 | Water Adding Device | 125w | 125w | ||

| 5 | Heating Power | 1.5kw | 1.5kw | ||

| 6 | Rotary Speed of Main Shaft | 660r/min | 660r/min | ||

| 7 | Overall Dimensions | 1500×700×1400mm | 1300×600×1300 mm |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

Plastic Grinding Milling Granulator

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

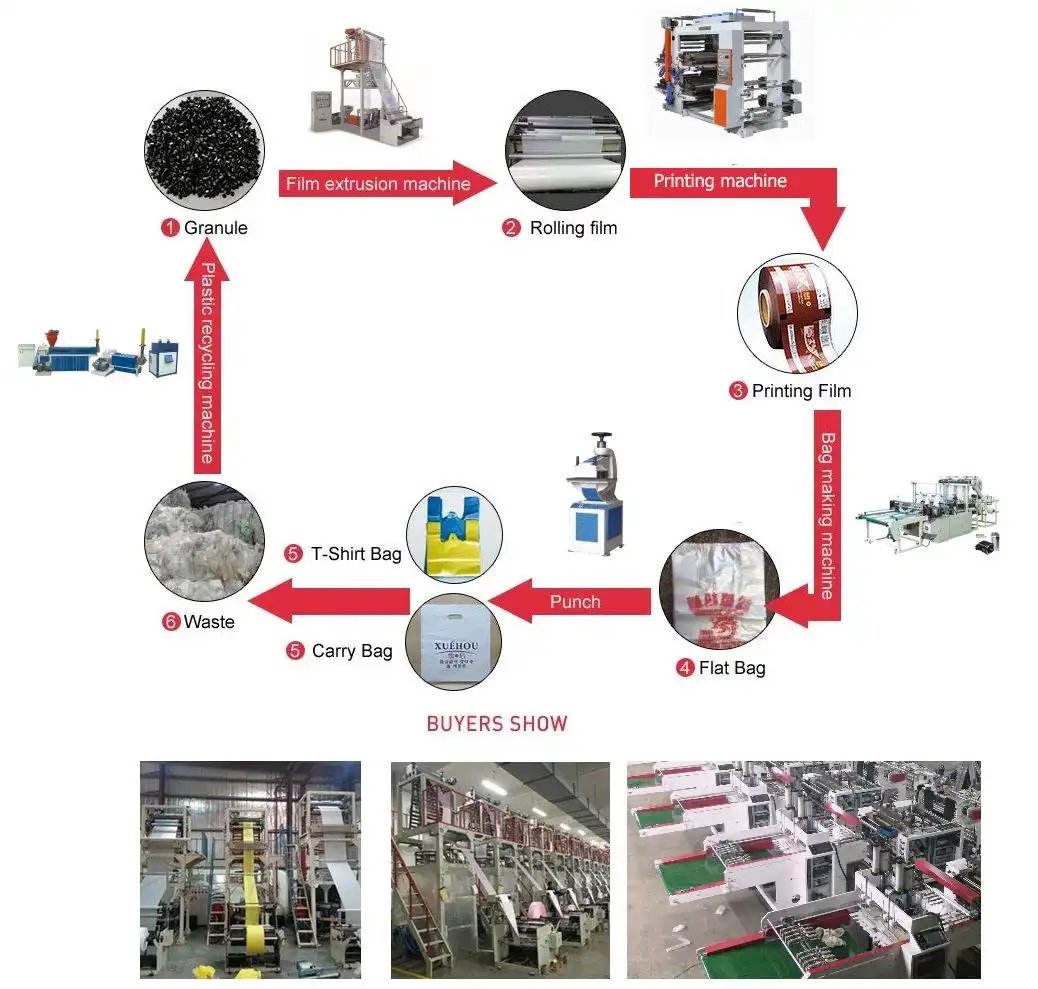

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Watsapp:008613088651008;