PVC Blown Film Extrusion adopts technologies such as rotary die head, frequency conversion speed regulation and automatic constant temperature control. The products produced have good plasticization, and the quality indicators of the film thickness uniformity, transparency, flatness, shrinkage and other quality indicators have reached the printing level. Thin film technical standards.

The pvc film blowing mechine is compact and easy to operate. It is mainly composed of the following parts: extruder, rotating die head, cooling air ring, first traction, hot water tank and calibrator, second traction (electric lift), double station Coiler, extruder electric control cabinet and auxiliary machine electric control cabinet.

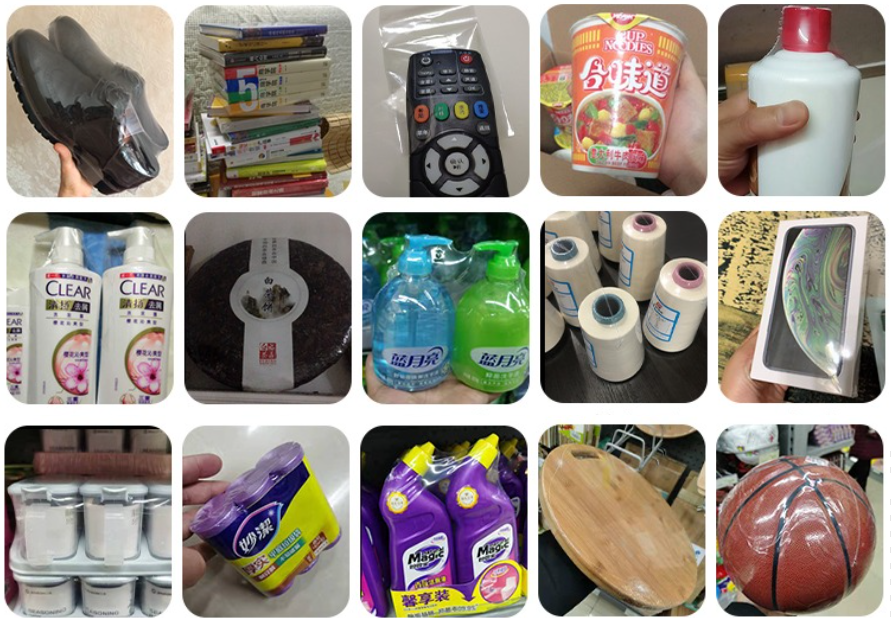

The pvc film blowing machine is suitable for heat-shrinkable films of various specifications made of PVC plastic resin blown by the tube film process. The film has the advantages of good transparency, good gloss, and high shrinkage. It is a popular new packaging material today and is widely used. Widely used in food, beverage, tea, glass products, handicrafts, sanitary ware, cosmetics, electronic products, etc.

PVC hot shrink film

|

Item |

SJ-P200 |

SJ-P400 |

|

Screw and barrel |

40mm |

45mm |

|

Screw Ratio |

28:1 |

28:1 |

|

Capacity |

18-35kg/h |

35-45kg/h |

|

Film width |

30-200mm |

150-400mm |

|

Film thickness |

0.01-0.08mm |

0.01-0.08mm |

|

Lateral shrinkage |

40-60% |

40-60% |

|

Longitudinal shrinkage |

4-25% |

4-25% |

|

Motor |

7.5kw |

11kw |

|

Machine weigth |

1800kg |

2000kg |

|

Machine size(mm) |

9000*1600*1500 |

9000*1600*1500 |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.