Side Sealing Machine also name BOPP bag machine,sealing knife also is cutting knife,seal and cut film at same time,suit to produce BOPP bag,PP bag,mailing bag,ice bag,HDPE bag,LDPE bag.

BOPP Bag Making Machine

BOPP bag making machine is suitable for heat sealing and cutting bags of BOPP, PP, PE and other materials. Suitable for making flower bags, triangle bags and candy bags.

1.Inveter control machine motor,control machine speed.

2.touch screen control machine speed and bag length.

3.Machine with photoscell,can produce printed bag and unprinted bag.

4.Machine with hole punch.

5.Machine with folding device(optional parts).

Suitable materials:

BOPP, PP, PE, POF, CPP etc. which can be used to heat and cut.

Produce products:

Clothing bag, socks bag, towel bag bread bag, ornaments bag, underwear bag, stationery bag, electric components bag, bamboo products and woodwork bag, etc.

BOPP bag

Main Technical Variables:

| Model | RQL-600 | RQL-800 | RQL-1000 | RQL-1200 | RQL-1400 | RQL-1500 |

| Width of sealing & cutting | 580mm | 750mm | 950mm | 1150mm | 1350mm | 1450mm |

| Length of sealing &cutting | 900mm | 900mm | 900mm | 900mm | 1000mm | 1000mm |

| Speed of bag-making | 40-180pc/min | 40-180pc/min | 40-180pc/min | 40-150pc/min | 40-150pc/min | 40-150pc/min |

| Main motor | 1.1kw | 1.1kw | 1.5kw | 1.5kw | 2.2kw | 2.2kw |

| Weight | 700kg | 800kg | 900kg | 1000kg | 1400kg | 1500kg |

| Outline dimension | 3.6*1.1*1.7M | 3.6*1.2*1.7M | 3.6*1.5*1.7M | 3.6*1.6*1.7M | 3.6*1.8*1.7M | 3.6*1.9*1.7M |

| Kind of Bag | BOPP bag,Bread Bag,Garment Bag, stationery Bag,DVD Bag,CD bag | |||||

| Bag of Material | HDPE、LDPE、PP、OPP、BOPP | |||||

| Power Voltage | 220V | |||||

| Machine Working Time | 24 hours * 7 days | |||||

| Warranty | 1 year | |||||

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

Our Main parts cooperator as following brand,but standard parts all made from China.

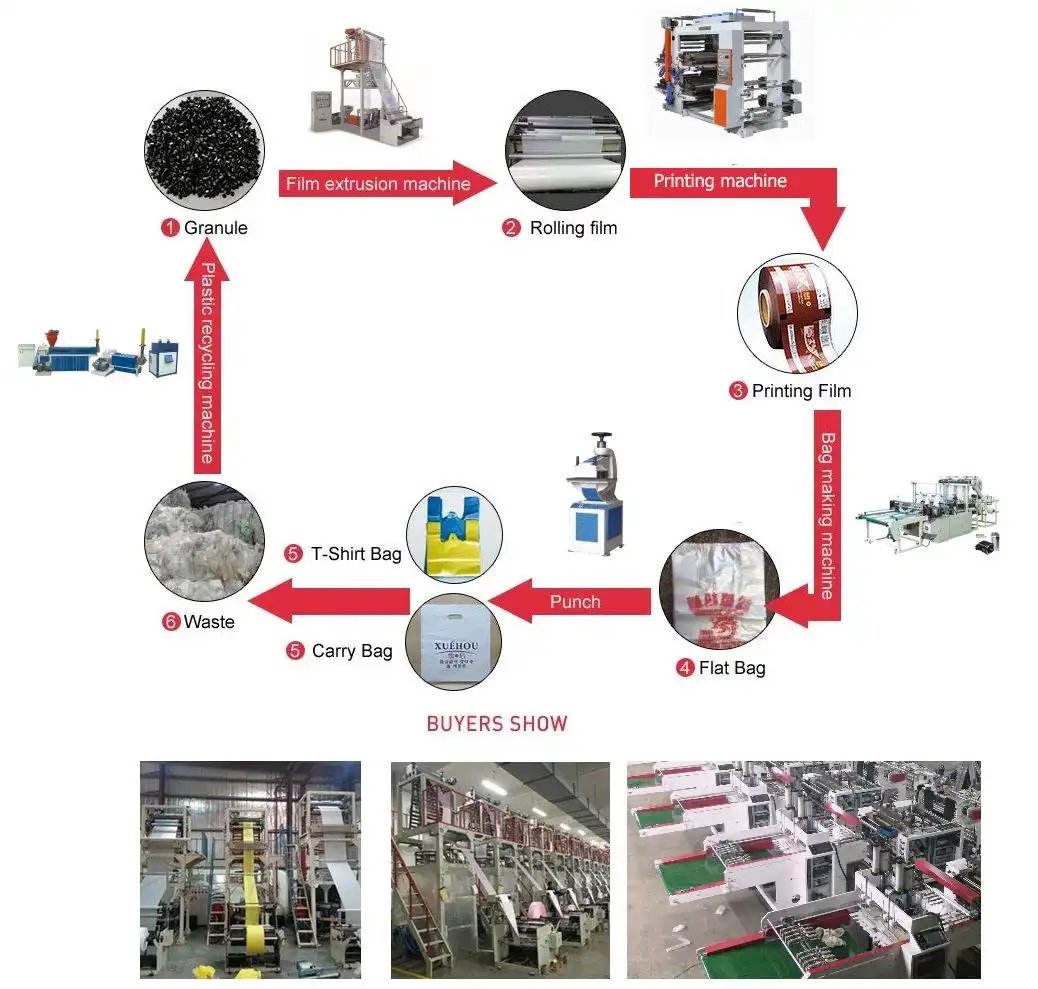

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Watsapp:008613088651008;